Get Rid of Old Age Inspection Methods

Precision Gauging & Inspection

Smart Manufacturing Also require Smart Inspection..Thats Why our Online Inspection solutions are the next Choice for 100% Online Inspection

Overview Precision Gauging

A perfect fit for Today's Manufacturing & Quality needs. Our Gauging Equipments are for 100% Online Measurement for Part dimensions & Characteristics with Accuracy of <1micron.

Dimensional Parameters

Diameter-Internal & External, Length, Step Length, Thickness,

Geometrical Parameters

Perpendicularity, Concentricity, Runout, References, Flatness, Ovalty, Variation etc

Temperature Compensation

Temperature compensation for Parts with Temperature sensitive operations and characteristics

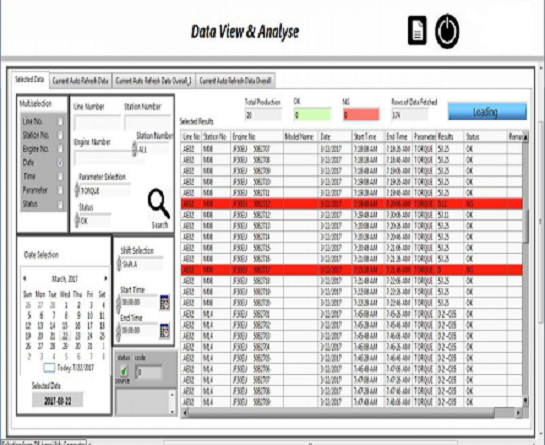

Data Recording & Traceability

100% data Recording and Traceability of Inspected parts with Direct Part Marked Laser Code and Traceability Application

Application Details

Few Application Areas has been Listed below but it doesn't limit of Varieties of application where it can be implemented. If Dimension Exists it can be inspection ..As simple As That

Cylinder Block Gauging

Cylinder Block Component Bore Inspection, Ovalty, Perpendicularity, Taper etc with Accuracy and repeatability of less than 1-micron.

Crank Shaft Gauging

Automotive Crank Shaft Assembly Runout Inspection 100% online with data Recording & traceability with Laser Barcode.

Cam Bore Gauging

Cylinder Head Cam Bore Diameter Inspection, Ovalty and Positioning Tolerance with Traceability & Temperature compensation.

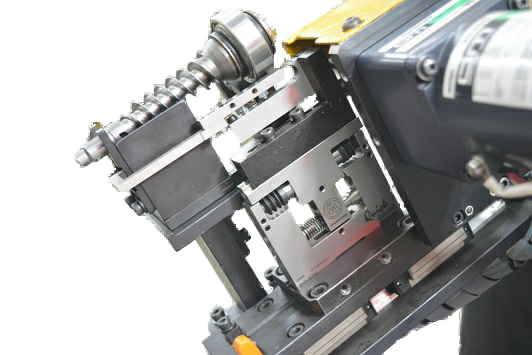

Mold Core Gauging

Mold Core Inspection for Investment Casting Mold Cores. Free to set desired Tolerances.

Shaft Component Gauging

Shaft Component Gauging & Inspection for Outer Diameter, Step Length, Step Diameter, Concentricity, Runout , Grinding Allowance and Auto Correction.

Frequently Asked Questions

Doubt are better when it generate questions, Questions are better when it leads to answers. Here are Few!

Our solutions are proven to inspect parts 100% in Production Environment & online

Data recording is Inbuild Feature of Our Precision Gauging Inspection systems. With Laser barcode or Printed Barcode Integration Traceability can be done.

YES! Geometrical Tolerance inspection is also possible. Theoritically speaking everything Mentioned on drawing can be Inspected but Cost need to be consider.